Version 1.0

Even though the protoboard computer works, and I successfully worked with it for months, it has some significant drawbacks:

- Difficult to modify

- Making any changes to the system requires maneuvering through a trunk of wires with an iron.

- Fragile

- Multiple wires are often joined to a single pad. This requires the solder joint to be reheated/reflowed multiple times. A wire that pops loose would be difficult to reattach.

- Not worth reproducing

- It took about three days of soldering to get the computer connected. Repeating that task is not something I was looking forward to.

A tricky thing about computers of this era is managing the bus lines between devices. The most common approach I've seen is the X-Y approach, where you have traces run top-to-bottom on one side, and left-to-right on the other. This allows the traces to be a lot straighter with the trade-off of needing a lot more vias to connect the traces between layers.

Because I wasn't sure if this was even going to work (and because I'm cheap) I set out with the goal of making the PCB as cheap as possible to fabricate. This meant keeping the board to 100x100mm and two layers.

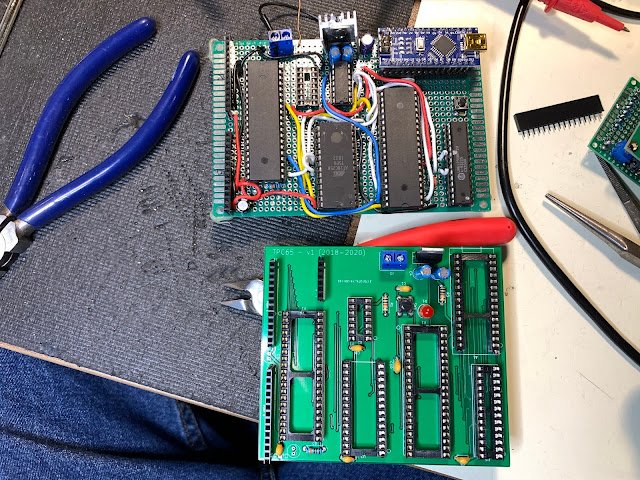

The first attempt was a direct copy of the hand-soldered computer, including all the mistakes made during construction:

The two boards shown above are functionally identical. Apart from one trace mistake, I only needed to move the components from board-to-board and it worked perfectly fine.

Version 2.0

- Fixing the mistakes made during construction

- Specifically aligning the bus lines with the Arduino Nano's ports for faster bitwise operations.

- Adding a second VIA

- Adding a dedicated SD card port

- Utilizes port A of the first VIA

And this, version 2 was born:

Hello

ReplyDeleteI came across your blog and was deeply impressed by your content, which I believe is of great value to electronic enthusiasts.

This is Liam from PCBWay, I would love to sponsor your project by providing free PCB prototyping. In return, I only ask for a slight promotion or a review about the quality or service you receive.

Would you be interested in partnering up? Contact me: liam@pcbway.com